- Materiały eksploatacyjne chevron_right

- Komory śrutownicze

Mobile Shot Blasting Chamber Based on Sandwich Panels

Tax included

zł344,400.00

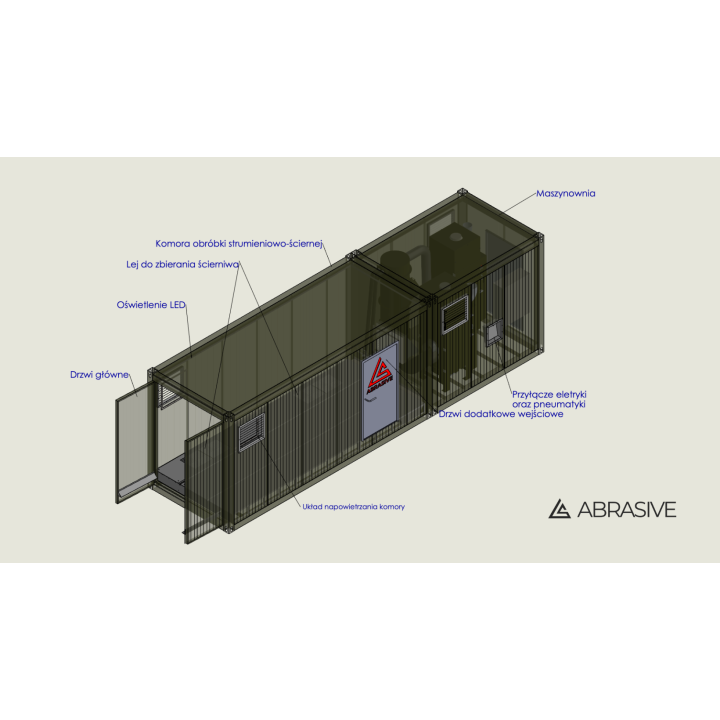

The mobile shot blasting chamber is designed for maximum functionality and ease of use in the field.

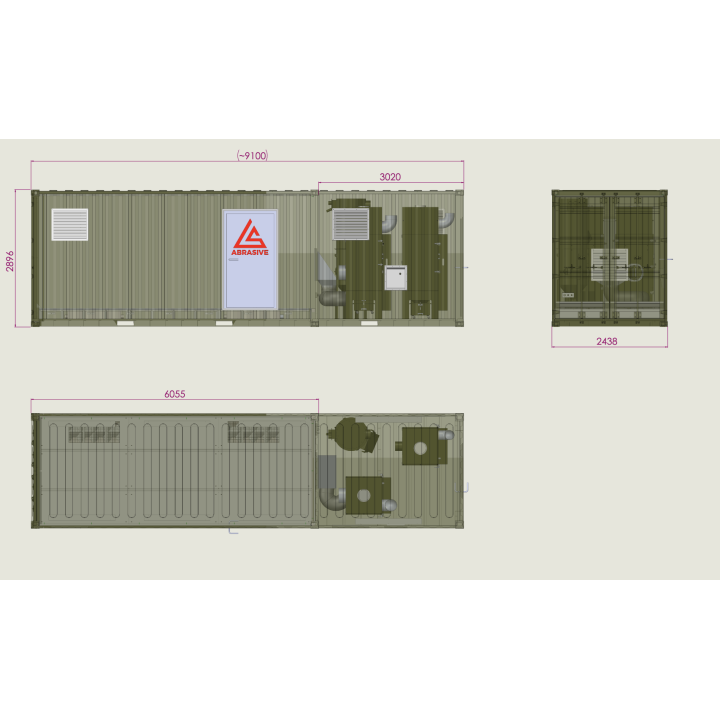

It is built on a sturdy 20 ft HC shipping container structure and features a complete dust extraction system, abrasive recovery system, and automation and control equipment. The chamber is equipped with solutions that ensure safe and comfortable operation.

An ideal solution for companies that need a flexible abrasive blasting workstation in multiple locations.

It is built on a sturdy 20 ft HC shipping container structure and features a complete dust extraction system, abrasive recovery system, and automation and control equipment. The chamber is equipped with solutions that ensure safe and comfortable operation.

An ideal solution for companies that need a flexible abrasive blasting workstation in multiple locations.

Benefits of Using the Shot Blasting Chamber:

1. Cleaning Efficiency

The shot blasting process in the chamber is highly effective at removing all types of contaminants, resulting in a higher quality of the treated surface.

2. Preparation for Finishing Coatings

Provides ideal surface preparation for painting or coating, eliminating old layers, rust, and other imperfections.

3. Versatility of Use

Can be applied to various materials, making it a versatile tool across different industries.

4. Time and Energy Savings

The fast shot blasting process saves time, and optimally selected components help reduce energy consumption.

Construction Variants:

| Parameter | Chamber Based on 20 ft HC Sea Container | Chamber Based on Sandwich Panel Construction (60 mm) |

|---|---|---|

| Working Chamber Dimensions (mm) | 5800×2300×2450 | 5800×2200×2500 |

| Doors | Front container doors (main), additional side doors (entrance) | Front container doors (main), additional side doors (entrance) |

| Abrasive Extraction | Pneumatic + two funnels in the floor | Pneumatic + two funnels in the floor |

| Dust Extraction System | Open air circulation | Open air circulation |

| Finishing Materials | Lined with abrasion-resistant material, floor made of checkered plate | Lined with abrasion-resistant material, floor made of checkered plate |

| Trackway | In the middle of the container | In the middle of the container |

| Lighting | Ceiling LED | Ceiling LED |

| Safety System | Light and sound signaling. Limit sensors. System compliant with OHS regulations | Light and sound signaling. Limit sensors. System compliant with OHS regulations |

The shot blasting chamber is a key industrial tool that ensures effective cleaning and surface preparation for further processing or painting, positively affecting the quality and durability of the final product.

Technical Equipment:

- Premium Brand PLC Control – intuitive control panel ensures precise operation and full process monitoring.

- Thermal Insulation – available as an option, enables operation in low-temperature conditions.

- Single Workstation – operated by one operator, compact and ergonomically designed.

Machine Room:

| Parameter | Chamber Based on 20 ft HC Sea Container | Chamber Based on Sandwich Panel Construction (60 mm) |

|---|---|---|

| Machine Room Dimensions (mm) | 2900×2300×2650 | 2900×2300×2650 |

| Doors | Additional side doors (entrance) | Additional side doors (entrance) |

| Blasting Pot / Reclaimer | 200 L with abrasive separator and full piping/valving | 200 L with abrasive separator and full piping/valving |

| Abrasive Separation | Abrasive separator adapted to the type of material | Abrasive separator adapted to the type of material |

| Abrasive Transport System | DDU MRA 400 (4 kW) | DDU MRA 400 (4 kW) |

| Ventilation System | DDU GMT 500 (4 kW) | DDU GMT 500 (4 kW) |

| Control | Control cabinet + safety system | Control cabinet + safety system |

| Automation | PLC controller + HMI panel | PLC controller + HMI panel |

Abrasive Recovery and Dust Extraction System

The product comes standard with Abrasive’s proprietary recovery and filtration system:

- Standard version with abrasive recovery channel and cyclone separators.

- Closed-loop recirculation – abrasive returns automatically without manual refilling or contact with waste.

- Professional filter fans with automatic pulse cleaning – ensure clean working air without the need for external exhaust systems.

Safety and Work Comfort

- Limit switches – the system automatically stops when doors or gates are opened.

- Light and sound indicators – provide work status information and improve safety.

- Durable LED lighting – power and brightness in compliance with standards.

Service, Transport, and Installation

- Full Abrasive Service – installation, commissioning, operator training, and access to spare parts and technical support.

- Transport – carried out independently (by truck). The offer is presented without transport costs, allowing flexible adjustment to the client’s location.

Why choose Abrasive?

- Mobility and fast deployment – the chamber is ready for use without foundations, installation within a few hours.

- High air quality and work comfort – dedicated in-house filtration system and automatic abrasive recirculation.

- Safety compliant with health and safety standards – complete set of safety features and PLC-controlled automation.

- Low operating costs – no mechanical scrapers and durable components free from frequent repairs.

- Comprehensive support – training, service, quick availability of spare parts, and expert assistance.

Price list (net)

- 20 ft HC shipping container – 250,000 PLN

- Sandwich panel container (60 mm thick) – 280,000 PLN

1 other product in the same category

Loading...

check_circle

check_circle

Comments (0)

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent